The research focuses on wood mainly as a renewable resource.

- We are dedicated to research into properties and structure of wood, wood-based materials, technologies for processing, millwork and use of wood and other materials for construction.

- Development is the goal from initial idea to patents used in practice in the areas of new materials, technologies and construction.

- Facilites for scientific work at the international level, providing specialized laboratories located in the university campus as well as the Josef Ressel Research Center.

- Laboratories are equipped with modern devices and equipment, some of which were developed at the department workplace and enable very specific research.

- Analyses and testing are performed as a part of research and education, but also serve general professional public within assessment and expert opinion services.

- Cooperation with foreign institutions within many projects, research internships abroad and presence of foreign colleagues as team members, is an essential part of quality research.

Following laboratories are currently administered by the department

The laboratory provides identification of wood samples, analysis of heartwood and sapwood formation at the cellular level, analysis of morphometric values of wood anatomical elements, and comparative anatomy of fossil wood.

Range of expertise:

Determination of wood samples at the macroscopic and microscopic levels (living wood, charred macro-residues, wood from archeological finds)

prof. Ing. Vladimír Gryc, Ph.D.

Department of Wood Science and Wood Processing Technology

ph.: +420 545 134 548, mobil: 773 771 033

e-mail: vladimir.gryc@mendelu.cz

Range of expertise:

Visual assessment of tree condition, proposal of interventions, verification of tree stability using acoustic tomography or a tensile test.

Ing. Luděk Praus, Ph.D.

Department of Wood Science and Wood Processing Technology

ph.: +420 545 134 551

e-mail: ludek.praus@mendelu.cz

The laboratory researches microwave modification of wood and wood-based materials.

Range of expertise:

Research into interaction between electromagnetic radiation and particular material for the purpose of plasticization, drying, acceleration of chemical reactions, adjustment of permeability, sterilization, etc.

Ing. Jakub Dömény, Ph.D.

Department of Wood Science and Wood Processing Technology

tel.: +420 545 134 550

e-mail: jakub.domeny@mendelu.cz

The laboratory provides dendrological dating, forms standard chronologies, researches into the use of wood throughout history, determines the origin of wood, and deals with dendro-ecological and dendro-climatological applications, including the use of isotope analysis.

Range of expertise:

Dendrochromological dating of historical wooden building structures, archeological and sub-fossil wood, musical instruments and pieces of art.

doc. Ing. Michal Rybníček, Ph.D.

Department of Wood Science and Wood Processing Technology

ph.: +420545 134 546

e-mail: michalryb@post.cz

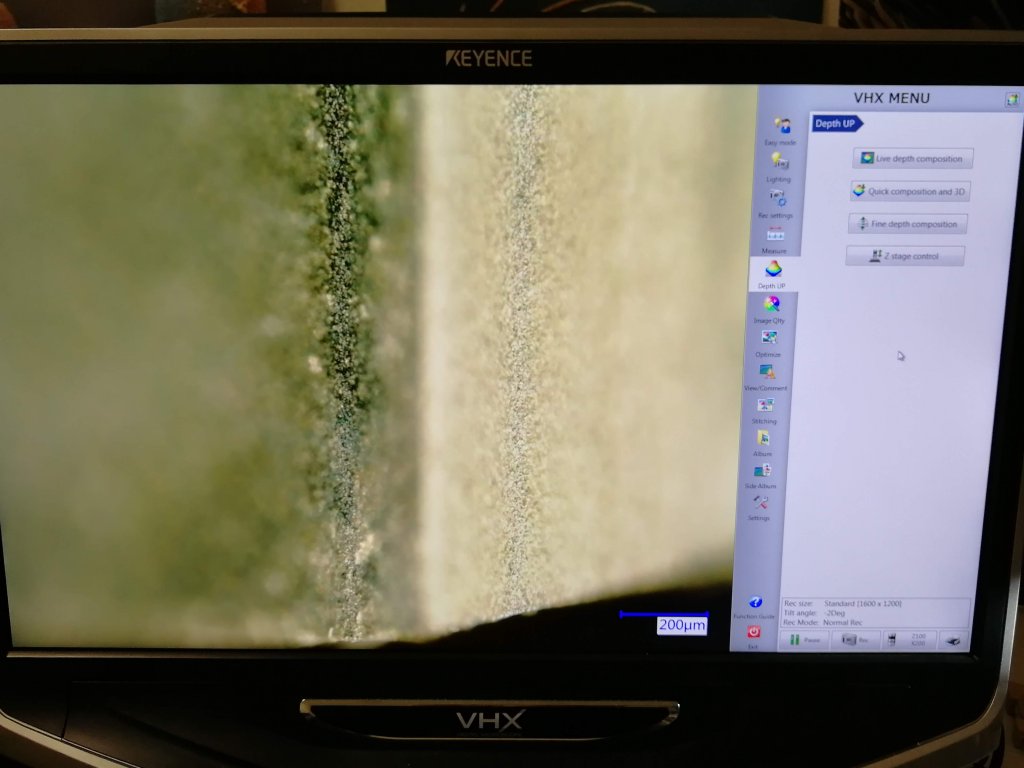

The laboratory evaluates cutting processes (circular saw cutting, milling) and the effect of the process conditions change on machining parameters.

Range of expertise:

Verification tests of cutting edge durability and tool lifespan, measurement and evaluation of machined material surface quality, measurement and evaluation of forces during simultaneous machining on 3 axes, calculations of cutting forces and resistance to the tool cutting edge, measurement and evaluation of tool noise level, dust production evaluation

Ing. Luďka Hanincová, Ph.D.

Department of Wood Science and Wood Processing Technology

ph.: +420 545 134 013

e-mail: ludka.hlaskova@mendelu.cz

The laboratory measures thermal and moisture properties of materials (thermal conductivity, thermal capacity, diffusion resistance factor, sorption, absorption).

Range of expertise:

Laboratory measurements, research and development of material properties in the field of thermal technology, building structure diagnostics, experimental measurements and modeling of the thermal-moisture regimen of building structures, analysis of building energy efficiency.

Ing. Richard Slávik, Ph.D.

Department of Wood Science and Wood Processing Technology

ph.: +420 545 134 159

e-mail: richard.slavik@mendelu.cz

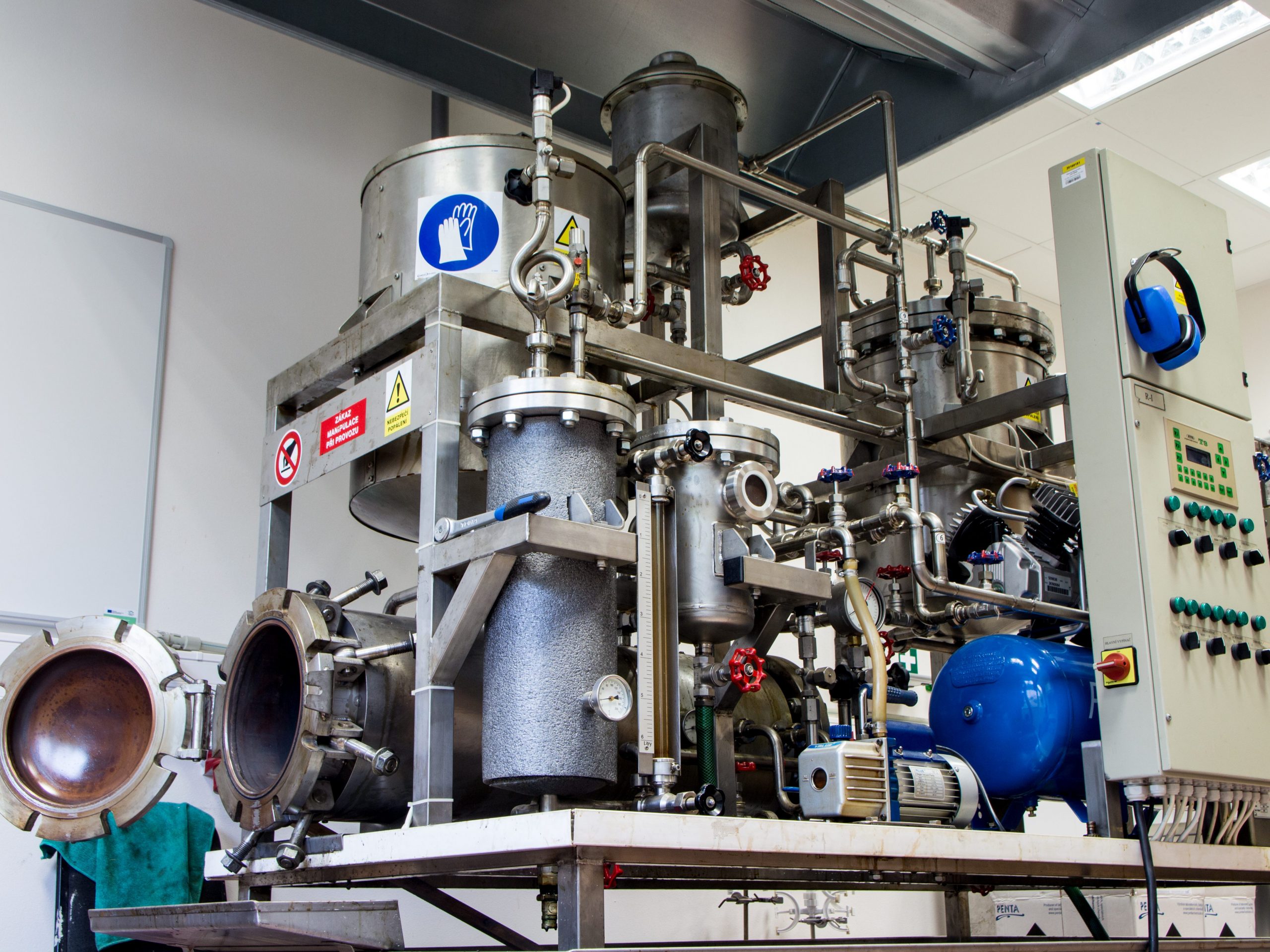

The laboratory examines vacuum-pressure impregnation as a modification method to increase suitable wood properties

Range of expertise:

Pressure impregnation of substances (water-soluble or oil based) into wood with option of temperature increase up to 160 °C. Research and development of technological processes of pressure impregnation and optimization of parameters (pressure, time, temperature, process, etc.). Determination of impregnating substance uptake.

Ing. Petr Pařil, Ph.D.

Department of Wood Science and Wood Processing Technology

ph.: +420 545 134 550

e-mail: xparil1@mendelu.cz

The laboratory researches the resistance of wood-based materials and modified wood to wood-degrading fungi, efficiency of fungicides, resistance of wood-based materials and wood surface treatments to the atmospheric corrosion during natural or artificial aging.

Range of expertise:

Laboratory testing of wood natural durability (wood decay fungi), effectiveness of wood preservatives (EN113), identification of wood-degrading pests, natural aging and artificial aging of wood-based materials and wood surface treatments.

Ing. Jan Baar, Ph.D.

Department of Wood Science and Wood Processing Technology

ph.: +420 545 134 046

e-mail: jan.baar@mendelu.cz

Laboratory applies suitable analytical methods to determine target elements in various matrices of the environment.

Range of expertise:

Value determination of dry matter, viscosity, pH, phenol, formaldehyde, extractive substances, total polyphenols, carbohydrates and starch (SPFM), selected individual volatile and non-volatile substances (GC-MS-TD-HS, HPLC-DAD- ELSD), etc. Matrix diagnoses of living wood, dead wood, adhesives, composite materials, wood-based materials, insects, soil, air samples, other biological materials

Mgr. Zuzana Paschová, Ph.D.

Department of Wood Science and Wood Processing Technology

ph.: +420 545 134 160

e-mail: zuzana.paschova@mendelu.cz

The laboratory examines thermal modification of wood with the purpose of elevating applicable properties of wood by targeted thermal degradation of fundamental chemical components of wood or by surface modification – carbonization.

Range of expertise:

Thermal modification process optimization for specific applications, i.e. determining temperature ranges of the thermal modification process with respect to the type of wood, determining weight loss, degree of color change, dimensional stability and mechanical properties of thermal modified wood.

Ing. Petr Čermák, Ph.D.

Department of Wood Science and Wood Processing Technology

ph.: +420 545 134 550

e-mail: xcerma24@mendelu.cz

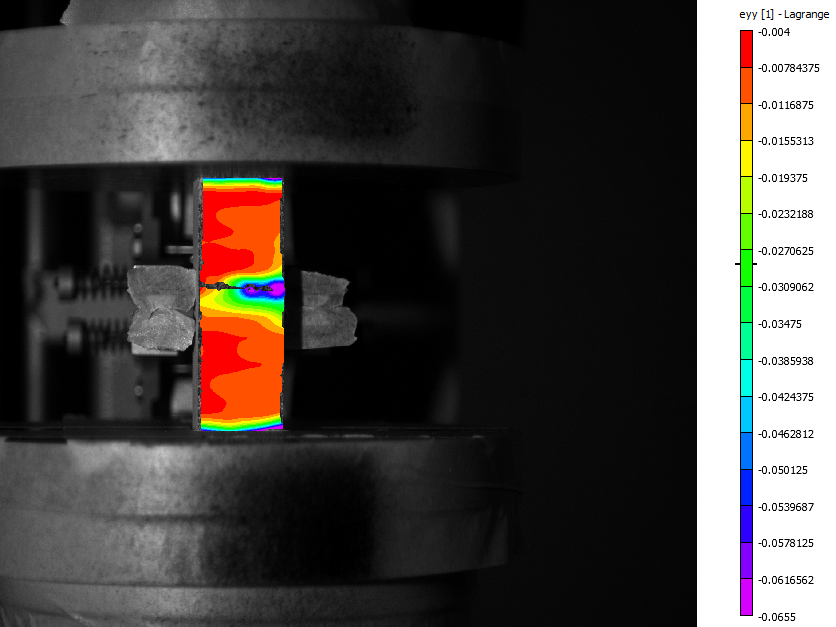

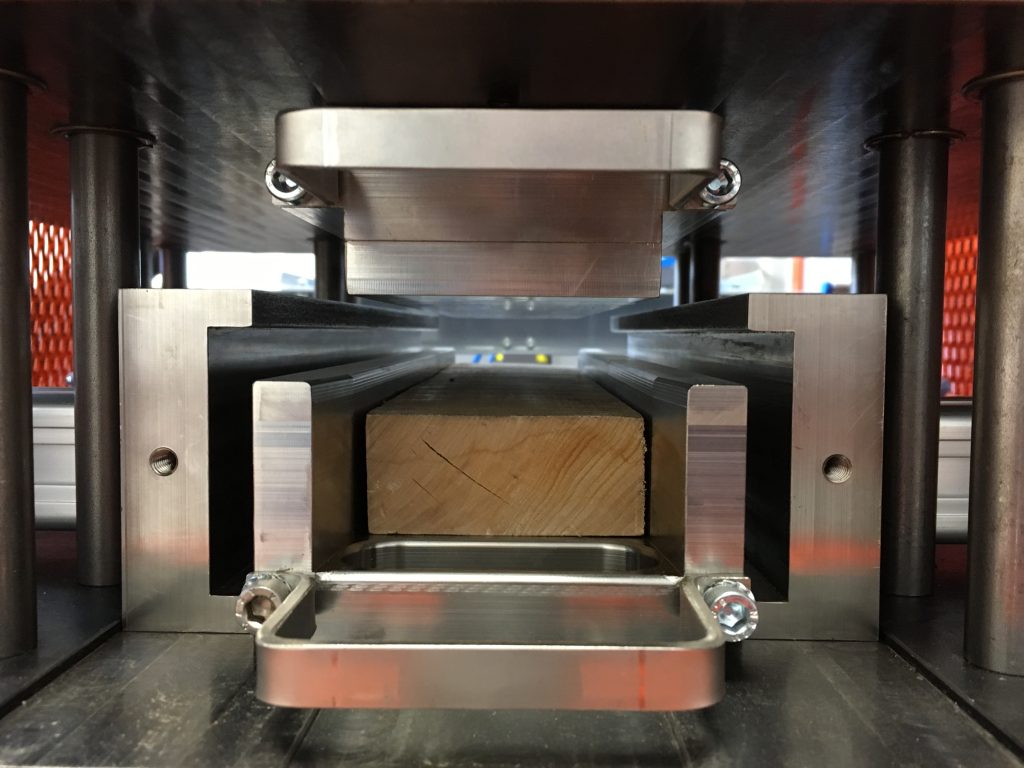

The laboratory identifies mechanical behavior of wood and wood-based materials in basic load conditions.

Range of expertise:

Determination of mechanical properties of wood and wood- based materials using small test samples and structural elements in compliance with Czech and international standards, analysis of deformation fields applying optical methods, determination of basic characteristics of structural joints.

Ing. Martin Brabec, Ph.D.

Department of Wood Science and Wood Processing Technology

ph.: +420 545 134 545

e-mail: xbrabec3@mendelu.cz

The laboratory processes calculations applying the finite element method.

Range of expertise:

Physical analyses and numerical calculations (mechanical, thermal, vibro-acoustic, etc.) of wood, wood-based materials and wooden structures.

Ing. Jan Tippner, Ph.D.

Department of Wood Science and Wood Processing Technology

ph.: +420 545 134 544

e-mail: jan.tippner@mendelu.cz

The laboratory identifies vibro-acoustic properties of wood and wood-based products.

Range of expertise:

Experimental determination of acoustic properties of materials, laser vibrometry, modal analysis.

Ing. Patrik Nop

Department of Wood Science and Wood Processing Technology

ph.: +420 545 134 045

e-mail: patrik.nop@mendelu.cz

The laboratory examines the development and laboratory production of layered and particle composite materials (particle board, OSB, plywood, etc.)

Range of expertise:

Development and optimization of production of layered and particle composites, i.e. determination of technological operations, optimization of particle size, determination of compression process parameters, verification of physical and mechanical properties of composite materials.

Ing. et Ing. Tomáš Pipíška, Ph.D.

Department of Wood Science and Wood Processing Technology

ph. +420 720 534 255

e-mail: tomas.pipiska@mendelu.cz

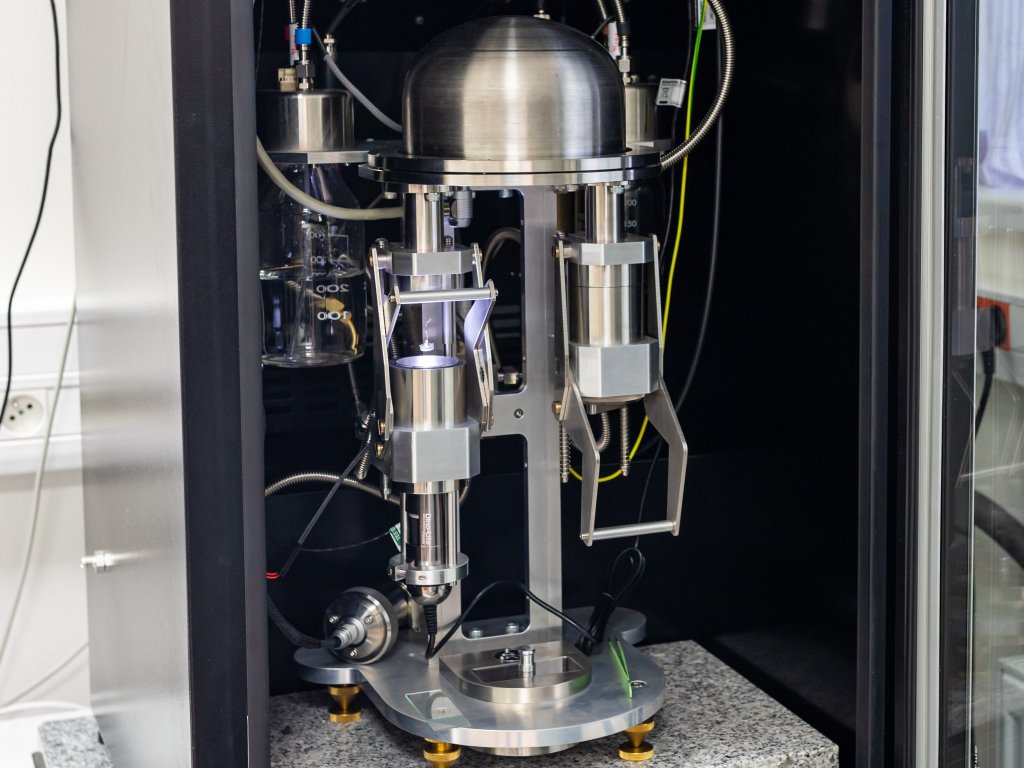

The laboratory examines surface treatment of wood and other materials using discharge plasma

Range of expertise:

Plasma activation and plasma treatment of the surface of flat and granular materials, analysis of the method effect on adhesion and surface fluid distribution.

doc. RNDr. Jozef Ráheľ, PhD.

Department of Wood Science and Wood Processing Technology

e-mail: jozef.rahel@mendelu.cz

The laboratories can pride themselves with special equipment:

- continuous microwave modification line,

- instrument for measuring dynamic sorption of water vapor and organic solvents SMS DVS Resolution,

- thermal modification chamber,

- ring knife slicer for particle board and OSB,

- thermal conductivity measurement (HFM Netzsch Lambda, Transient RTB, AP ISOMET 2114)

- measurement of material sorption applying methods compliant with EN 12571,

- measurement of material diffusion properties using the DRY CUP and WET CUP methods compliant with EN 12572

- measurement of porosity and pore distribution using the mercury porosimetry method Quantachrome PoreMaster 33GT,

- piezoelectric dynamometer Kistler 9257B,

- acquisition sets for 2D and 3D optical deformation measurement.

As a result we gain significant projects and publications

- GACR – Experimental and numerical estimation of the notch capacity in structural timber beams in a general location using LEFM

- Erasmus+ – Interdisciplinary, collaborative learning and teaching for resilient wood resources and innovations in a digital world (Wood+)

- Erasmus+ – Digital support of educational methods in situations complicating practical training on CNC technologies in the field of wood processing

- MPO (OP PIK) – Research and development of furniture parts with reduced flammability in the company Jan Ficek Dřevovýroba s.r.o.

- NAZV – Optimizing cultivation practices for adaptation of forest ecosystems to climate change

- Ministry of Education and Culture (ERC CZ) – Tree dynamics: description of mechanical response to load

- Ministry of Education and Culture (INTER-EXCELLENCE II) – Analysis of the properties of lesser-known European wood species in composite materials

- TAČR – Database of tree-ring chronologies as a tool for recording and predicting the response of the main forest species to climate change

- TAČR – Innovative design and production technology of wooden panels

- FFG (Comet) – I3 Sense: Development of advanced sensors for wood-based composites

- Interreg – DreVeSta: Wood in construction – a material of the past and the future

- Interreg – VALID: Added Value from Residuals ( 2020 – 2021)

- Interreg – ROTCUT: From Linear to Rotary Cutting of Hardwood ( 2021 – 2022)

- Interreg – HARDIS: Mechanical disintegration of hardwoods (2017 – 2020)

- Horizon – ASFORCLIC: Adaptation strategies for Climate Changes (2021 – 2022)

- MPO (OP PIK) – Beech modification (2017 – 2019)

- MPO (OP PIK) – Development of equipment for the production of carbonized wood surfaces (2020 – 2022)

- MPO (TRIO) – Composite sandwich elements for the construction of wood-glass facade systems (2017 – 2019)

- TAČR – Progressive design and management of drying ovens for hard-to-dry woods, including exotic ones (2018 – 2019) GAČR – Climate and air pollution effects on forest productivity (2018 – 2020)

- GAČR – Extension the Czech Millennia-long Oak Tree-ring width Chronology (2018 – 2020)

- GAČR – Reconstruction of hydro-climatic conditions of spring and summer of the last millennium in the Czech Republic based on the oak standard chronology

- GAČR – Hygro-thermo-mechanical behavior of modified wood- based materials at different levels of observation (2019 – 2021)

- TAČR – Oak fasteners in wooden constructions: basis for normative anchoring (2018 – 2019)

- TAČR – Construction and development of unique sheet composite elements based on wood for sports and theater floors (2017 – 2019)

- TAČR – Progressive design and management of drying ovens for hard-to-dry woods, including exotic ones (2018 – 2019)

- TAČR – Historical wooden structures: typology, diagnostics and traditional woodworking (2016 – 2020)

- TAČR – Elimination of moisture load on musical instruments (2016 – 2020)

- TAČR – Center for Advanced Materials and Efficient Buildings (2019 – 2020)

- TAČR – Development of surface carbonization technology for wooden building elements: elimination of moisture and biodegradation effects (2019 – 2021)

- TAČR – Rod elements of the framework of wooden construction using hardwood (2019 – 2021)

- TAČR – Anisotropic character of hygroexpansion in modified wood (2018 – 2019)

- TAČR – Construction and development of unique surface composite elements based on wood for sports and theater floors (2017 – 2019)

Go to the University Information System.

Cooperation:

- Asociace dodavatelů montovaných domů

- Bednářství Bařina

- Bednářství Fryzelka s.r.o.

- BPK s.r.o.

- Centrum pasivního domu

- DEK a.s.

- DIPRO, výrobní družstvo invalidů

- Dřevoterm s.r.o.

- DŘEVOZÁVOD PRAŽAN s.r.o.

- Erodach s.r.o.

- KATR s.r.o.

- Kompan Czech Republic s.r.o.

- LABE WOOD s.r.o.

- Lesy ČR s.p.

- Matrix a.s.

- Mayr-Melnhof Holz Paskov s.r.o.

- Miloslav Vlk s.r.o.

- Moravské dřeovstavby s.r.o.

- Nadace dřevo pro život

- Pila Javořice a.s.

- Pila Tetčice a.s.

- Sapeli a.s.

- SETORA s.r.o.

- Společenstvo dřevozpracujících podniků v ČR

- Stora Enso Wood Products s.r.o

- Vydona s.r.o.

- Wotan Forest a.s.

- Akademie výtvarných umění v Praze

- Archaia Brno z.ú.

- Archaia Praha, z.ú.

- Česká zemědělská univerzita v Praze

- České vysoké učení technické v Praze

- Muzeum Podblanicka

- Muzeum v přírodě Vysočina

- Muzeum vesnice jihovýchodní Moravy

- Muzeum vesnických staveb středního Povltaví

- Národní památkový ústav

- Ostravské muzeum

- Technické muzeum v Brně

- Ústav teoretické a aplikované mechaniky Akademie věd České republiky

- Valašské muzeum v přírodě

- Východočeské muzeum v Pardubicích

- Vysoké učení technické v Brně

- CESI Ecole d’ingénieurs F PARIS335

- Icelandic Forest Research Mógilsá

- NIBIO Svanhovd

- Salzburg University of Applied Sciences

- Slovenian Forestry Institut

- Slovenská Technická Univerzita v Bratislave

- Technická univerzita v Košiciach

- Technická univerzita vo Zvolene

- University College Dublin

- University for Sustainable Development Eberswalde

- University of Cambridge

- University of Freiburg

- University of Life Sciences in Poznan

- University of Ljubljana

- University of Lorraine

- University of Natural Resources and Life Sciences

- University of Primorska

- University of Valladolid

- Warsaw University of Life Sciences

- Žilinská univerzita v Žiline

Doctoral studies

Students of the doctoral study program apply their professional erudition in scientific, research, project, or teaching activities. They present their knowledge gained and the results of their research activities through numerous publications.

Materiálové inženýrství dřeva (in Czech)

Wood Material Engineering (in English)